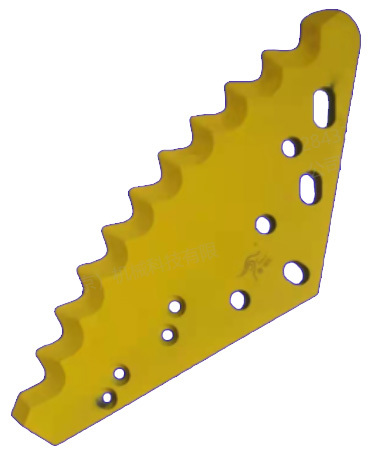

TMR Blade

Keywords:

AoXin

Category:

Product Description

Function

Cutting coarse fibrous materials

For high-fiber materials such as straw, hay, and silage, the blades use the shear force generated by high-speed rotation to cut these materials into shorter segments—typically 3–5 centimeters in length—thereby breaking down the fibrous structure. This not only makes it easier to mix the material later with concentrated feeds like corn or soybean meal but also enhances livestock’s ability to consume and digest the feed efficiently, preventing issues such as feed refusal or incomplete digestion caused by excessively long fibers.

Crushing large chunks of material

For compacted silage, dry and rigid straw, or frozen materials, the sharp edges of the blades can directly break up clumps, reducing large chunks into uniform small particles. This prevents the formation of "unmixed large masses" during the mixing process, ensuring that all materials are evenly incorporated into the subsequent blending operation.

Refine material granularity

By adjusting the blade speed or number of blades, you can control the degree of material crushing: for instance, when processing feed for young livestock, the material needs to be cut finer (particle size of 1–2 cm) to match their digestive capabilities; in contrast, feed for adult ruminants can retain slightly longer fibers to stimulate rumen motility. The precision of the blades directly determines the uniformity of the feed particle size.

Enhance material mixing efficiency

As the blades cut, they simultaneously cause the material to tumble vigorously within the mixing chamber, ensuring thorough intermingling of materials with varying densities and types—such as lightweight straw and heavier concentrated feed. In particular, in equipment equipped with dual or multiple augers, the blades work in harmony with the spiral vanes to create a three-dimensional mixing effect, minimizing material layering and significantly enhancing the uniformity of the final blend.

Adaptable to different material properties

The blade material—such as high-strength alloy steel—and its shape—like straight or serrated edges—can be adjusted based on the material properties: serrated edges are ideal for cutting tough straw, while straight edges work best for softer materials like silage. Additionally, wear-resistant materials are perfect for handling materials containing more dirt and sand, ensuring longer service life.

Related Products

Online Quotation Request

If you're interested in our products, please leave your email, and we'll get back to you as soon as possible. Thank you!