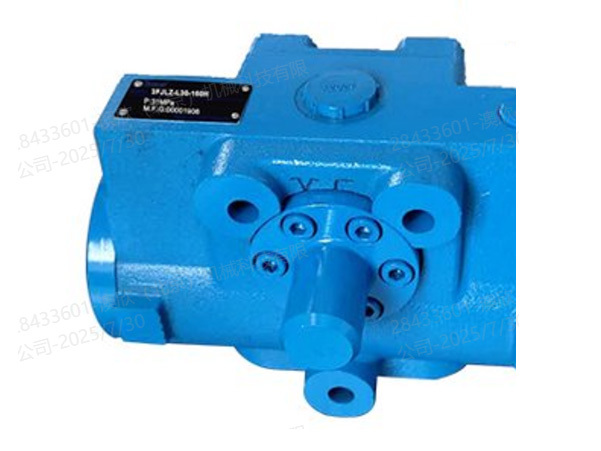

Material Distribution Vehicle Flow Control Valve

Keywords:

AoXin

Category:

Product Description

Function

Diversion function: A high-pressure oil flow from the hydraulic pump is divided into two or more streams according to a predefined ratio (e.g., 1:1, 2:1, etc.), which are then supplied to different actuators. This ensures that each actuator receives its intended flow rate even when subjected to significantly varying loads, enabling proportional motion—for instance, allowing dual cylinders to extend and retract at different speeds as required.

Current collection function: The oil flows returned from multiple actuators are combined into a single stream, typically used in scenarios where actuators need to stop synchronously or return oil collectively—preventing discrepancies in action timing caused by differences in return oil resistance.

Synchronous Control: In applications requiring strict synchronization among multiple actuators—such as crane telescopic booms or multi-cylinder-driven hydraulic lifting platforms—forced flow distribution is used to counteract load differences that could otherwise affect speed, ensuring all actuators maintain identical motion rates (e.g., both cylinders rising and lowering simultaneously with consistent stroke lengths).

Flow compensation: When an actuator experiences reduced flow due to increased load, the valve's feedback mechanism automatically adjusts by "topping up" the flow from other actuators, ensuring stable overall flow distribution and preventing sluggish movements or imbalances in speed.

Related Products

Online Quotation Request

If you're interested in our products, please leave your email, and we'll get back to you as soon as possible. Thank you!